Indoor air quality complaints from employees can be quite common in office environments. Symptoms such as red or itching eyes, cough, colds, allergies, headaches and unusual odors are some of the issues that can be reported by building occupants. In the course of investigating contributing causes, a review of the buildings use history, inspection of the immediate complaint area and measurement of various airborne contaminants may not reveal a likely source. This is when a trip to the air handling unit (AHU) on the roof becomes necessary.

Read MoreEnvironmental Health and Safety Blog | EHSWire

Spring Cleaning: What About Your HVAC System?

Posted by Emilcott Associates

Topics: indoor environmental issues, indoor environmental air quality, indoor air quality, indoor air quality evaluations, dust control, Mold, air pollution, indoor environmental quality, HVAC, AHU

What should you know about mold assessment and remediation in indoor environments in New York State (NYS) as of January 1, 2016?

Read MoreTopics: Mold, mold assessor

At Emilcott, 2011 was a successful year where we were able to tackle new projects, serve our clients and continue to respond to current industry issues in the environmental, health and safety field. Though we have had many great memories from 2011, we would like to mention some of the things that stood out most in our business for 2011.

Hurricane Irene the immense and powerful Atlantic hurricane that left a path of destruction and devastation was something that definitely stands out in 2011. We remember this event not only because of the wreckage caused by the storm, but also because of the after effects. The staff at Emilcott recognized the importance of addressing the legacy of water intrusion and the promise of mold after the storm and stressed to clients the importance of timing to address how to respond to this problem, as well as the importance of selecting the proper remediation technique along with an EHS mold expert and Emilcotts mold remediation strategy. (Read more: Hurricane Irene Leaves a Legacy of Water Intrusion and the Promise of Mold)

Energy Sector Emilcott has been thrilled to be able to participate in many different initiatives within the energy sector. Regionally important to the growth of our economy, the ongoing infrastructure improvements have given us substantial health and safety support work. In EHSWire during 2011 we addressed many occupational hazards as Occupational Heat-related Illnesses where we went over the symptoms that workers may experience, as well as what should be done if someone does experience these symptoms. Besides dealing with working conditions such as heat, Emilcott also provided information on the truths about occupational slips, trips and falls which ended up costing American businesses $13.67 billion in workers compensation costs in 2008. Adhering to proper safety protocols and preventing injuries is something that benefits businesses and their workers. OSHA provides a Walking/Working Surfaces Safety and Health Topic page which provides links to all the applicable standards.

With issues such as heat affecting the health of workers to preventing injuries on job sites, Emilcott has seen our fair share of mishaps. Being able to share our experiences and knowledge with others never gets old. From teaching someone the hazards about working near a crane, or things you should do when working in certain environments, Emilcott has always tried keeping people in the loop. We even have a 10-Hour Construction Industry Outreach Training Course based on the requirements established by OSHA which is a very hands-on and interactive class that we recommend to avoid a future work related issue. (Read more: Work Near a CRANE? Learn the Hazards!)

9/11 Tenth Anniversary focused the changes that have occurred since 9/11/2001 such as the new precautions that have taken place on the American Chemical Security issue. The DHS (the Department of Homeland Security) has been increasing their focus on utilities and chemical facilities which may become targets for terrorist activities and the DHS Chemical Facility Anti-Terrorism Standard (CFATS) now requires completing and submitting a Top Screen analysis to the DHS.

The James Zadroga Act , which was authorized to broaden, renew funding and extend benefits to Ground Zero workers whose death was a result of exposure, is of great significance and has put new emphasis on the importance of proper real-time environmental site monitoring. New technologies are available to protect site workers and the public from exposure to hazardous substances such as those from the collapse of the WTC towers. (Read more: 9/11 Tenth Anniversary Focuses on American Chemical Security)

Toxic Substance Control Act (TSCA) was of major importance not only to Emilcott, but also to facilities who are manufacturers or importers of chemicals in amounts of 25,000 pounds or greater. With so many questions regarding TSCA and the changes, Emilcott decided to put on a free webinar along with posting a number of blogs that answered many of the concerns our clients had. Emilcott was able to use its expertise and help many clients with TSCA compliance questions and concerns regarding the developments of IUR reporting and reporting obligations in 2011 for the calendar year 2010. (Read more: August 2011 Update on the TSCA IUR-now-CDR Rule)

Though Emilcott has had many remarkable memories of 2011, we felt these 4 really left an impression on our business. Emilcott is privileged to know that we were able to assist our clients in many different businesses not only in 2011, but throughout our history. Emilcott looks forward to a productive 2012 and we are excited to see what this year has in store for us.

Do you have any environmental, health or safety concerns for 2012? If so, please share them with us below!

Topics: Emilcott, OSHA, health and safety, CFATS, Hazardous Materials, worker safety, Occupational Health, Occupational Safety, TSCA, Toxic Substance Control Act, Uncategorized, Mold

Hurricane Irene Leaves a Legacy of Water Intrusion and the Promise of Mold

Posted by Shivi Kakar

With the departure of Hurricane Irene, many buildings throughout NJ and NY have sustained a wide range of water damage and require action to remediate or otherwise mitigate the impacts of water intrusion: mold, fungus and structural damage.

Timing is a key element in this response; immediate action is necessary to minimize the potential for mold growth within the building envelope. As in medicine, early detection leads to an early (and usually less expensive) cure. Time and water combined can grow to be an expensive and time-consuming enemy. Failure to respond promptly will very likely result in mold growth requiring significantly more demolition than if the condition is handled in a timely manner. What is the definition of “timely”? As soon as mold is discovered!

Experts Can Determine Proper Mold Remediation

Along with timing, selection of the proper remediation technique for the building’s water intrusion and moisture problem (removal, drying in place using fans and/or dehumidification equipment, cleaning, treatment with biocide, etc.) is essential for maintaining a safe building. Improperly implemented remediation procedures can result in cross-contamination and hidden mold growth areas which could adversely impact occupants as time passes while increasing overall remediation time and costs .

Water and flood remediation procedures vary and are dependent upon the convoluted mix of building materials, building design, furnishings, extent of exposure, and the source of the water. Water intrusion investigations and cleanup can be especially challenging in buildings such as multi-unit residences, hospitals or rehab centers, schools and older buildings. There are a wide range of environmental, health and safety (EHS) issues associated with commercial, industrial and institutional facilities; it is important to manage the project as well as the complex interaction between employees, contractors, and the public within a facility; the buildings themselves; and the physical surroundings where they are located.

Mold Remediation Services

An EHS mold expert will identify and eliminate sources of mold and other Indoor Environmental Quality problems. They will also provide a detailed project roadmap for cleanup and removal as well as project oversight for safe and effective remediation. Emilcott’s mold remediation strategy for safe and effective mold removal (with minimal damage to the building and reduced impacts to building occupants) includes the following steps:

Step 1: Initial Assessment

Locate the source of the moisture without deconstruction or disruption to the building and occupants. Determine the urgency of the mold problem and its impact upon workers or residents.

Topics: indoor air quality, General Industry H&S, General EHS, Construction H&S, Emergency Response, Air Monitoring, Mold, water, expert, irene, new york, hurricane, remediation, new jersey, flood, intrusion

Green Buildings Solving One Problem, Creating New Hazards?

Posted by Shivi Kakar

We all know what Green Buildings are, right? There are various permutations but generally, to be green, the structure is designed, built, maintained and sustained in an environmentally responsible and resource-efficient manner. The end-all objective is to reduce impact of the built package and system on both the environment and mankind by

- Using energy, water, and other resources efficiently

- Protecting occupant health

- Improving employee productivity

- Reducing pollution and waste

As a LEED AP-certified professional who specializes in Indoor Environmental issues with a focus on fire and life safety, I was very interested in recent articles that are creating awareness of some critical health and safety problems inherent to the green building movement that 1) use innovative, locally-produced products, and 2) implement new design, construction, and operation approaches intended to reduce energy usage and be environmentally sound.

Green Building Fire Safety

In Megan Grennilles recent EHSWire article about the seminal Triangle Fire, it noted that building and fire code rules caught up with the high rise construction only after the tragedy of 146 worker deaths highlighted the challenges of safety and rescue in the case of a fire. The same situation recently occurred in Bakersfield where a green-constructed Target store highlighted some new concerns for health and safety for emergency responders:

The fire at the Bakersfield Target started, firefighters learned, at the photovoltaic array [solar] on the building's roof. Even after the firefighters disconnected the electrical mains, they discovered that the solar panels were still energized, presenting a safety challenge in addition to the fire.

This brings to light how the integration of green building practices on a seemingly typical commercial building can present new hazards that must be identified to protect building occupants and emergency responders. Fire fighters responding to an alarm may cut electrical power from the supply grid, but what is the procedure if there is an active solar array or an integrated wind turbine generating power as a part of the building? Other new electrical and fire hazards facing unprepared emergency responders include the unknown level of fire resistance of recycled/green building materials, how to control fire spread on green vegetative roofs, and how to control smoke in wide, open atrium areas.

owners of green buildings might have to be aware that the green designs can present previously unconsidered challenges that arise as a direct result of construction choices. ...Because codes even a decade after green design concepts hit the mainstream still largely deal with traditional building designs and materials, facility managers have to know how to address the intersection of green design and current codes.

The bottom line is that "green concepts should be reviewed as part of a fire-protection and life-safety analysis, because buildings, green or not, must meet building and fire code standards to protect the health and safety of both the occupants and emergency responders.

Moisture and Mold Management in Green Buildings

Another potential hazard of green buildings is the management of moisture within the building and how selection of a green design and materials may be inappropriate if the location and weather are not considered: the design-and-construction community must not assume that if one builds green, then one will be building regionally correct or even lower risk buildings.

A recent article, Hidden Risks of Green Buildings, was written from an insurance underwriters perspective and centered on the management of moisture. The article mentioned the trend of using carbohydrate-based building products instead of petroleum-based building products. That is where my eyes widened! Any indoor quality consultant knows the formula: moisture + food source = perfect habitat for mold growth. Carbohydrate-based building products are food for mold!

Moisture comes from many sources in a building: bulk water from a rook, window, or facade leak; water pipe break; HVAC condensate overflow; condensation on cold surfaces; or vapor (relative humidity) in the air. Additional humidity can be added to the air by introducing humid outdoor air that has not been properly dehumidified or from other sources such as showers, locker rooms, steam rooms, gyms, kitchen facilities, human respiration (particularly if more people are occupying the space than the original design). ( More information on these moisture-related potential problems including the risk of LEED flush-outs can be found here.)

Moisture meeting carbohydrate-based building materials over time certainly does look like the potential beginning of The Perfect Storm, because, in reality, carbohydrate-based building materials, even treated with the best biocide, would only be mold resistant not mold proof. Given food, water, and time mold will grow. So as a professional IEQ consultant who has seen it all when it comes to mold contamination, I sincerely believe the articles foreshadowing that the design community would be advised to prioritize the lessons already learned from the waterproofing, humidity control, and building forensics community. When using potential mold food within a building, moisture control is ever more critical to the air quality of the building as well as the building materials life cycle.

Are you interested in green construction? Have you thought of the potential hazards that can be created when using new technologies, new materials and tightening up the envelope?

Topics: indoor air quality, health and safety, General EHS, Construction H&S, Emergency Response, worker safety, Air Sampling, Mold, Fire Safety, Exposure, Respiratory, green buildings, Working Green

Renovations to Older Buildings: Think About Lead Paint (and More) or Repent!

Posted by Shivi Kakar

As part of a standard, pre-work permit inspection by the local township, it was discovered the exterior of a church (and local pre-school) had been painted with lead-based paint! Unfortunately, the estimates to remove and repaint the church were far beyond the churchs budget. At the acrimonious and finger-pointing church review meeting, a voice suddenly called out, Ill take care of it for half the cost of the lowest estimate! Salvation!

However, when the contractor began the job, he learned that the cost of removal and repainting would be much more than he expected. In a panic, he did not remove the old paint and, to save materials cost, he diluted the new paint by 50% with water!

After the job was completed, a joyous church service was held to honor the contractor. In the midst of the service, a thunderstorm broke out and the congregants began to notice that the paint was literally washing off the building. The bewildered minister raised his arms and called out, Oh, Lord, what are we to do?" In reply, a booming voice from above called out, Re-paint! Re-paint!

I suppose the EPA heard this story as well because, on April 22, 2008, the EPA issued a rule requiring the use of lead-safe practices when engaging in renovation and painting projects that disturb lead-based paint in homes, child care facilities, and schools built before 1978. Under the rule, beginning April 22, 2010, contractors must be certified and must follow specific work practices to prevent lead contamination. Individuals can become certified renovators by taking an eight-hour training course from an EPA-approved training provider.

This rule applies to all renovations performed for compensation in target housing (housing constructed prior to 1978, except housing for the elderly or persons with disabilities --unless a child of less than 6 years of age resides or is expected to reside) and child-occupied facilities, except for the following:

- Renovations in target housing or child-occupied facilities in which a written determination has been made by an inspector or risk assessor that the components affected by the renovation are free of paint or other surface coatings that contain lead equal to or in excess of 1.0 milligrams/per square centimeter (mg/cm2) or 0.5% by weight, where the firm performing the renovation has obtained a copy of the determination.

- Renovations in target housing or child-occupied facilities in which a certified renovator, using an EPA recognized test kit and following the kit manufacturer's instructions, has tested each component affected by the renovation and determined that the components are free of paint or other surface coatings that contain lead equal to or in excess of 1.0 mg/cm2 or 0.5% by weight.

Lead poisonings in an office or domestic setting are mostly caused by exposure to lead dust. Here are a few facts:

- Lead dust settles quickly on floors, window sills and other surfaces.

- Paint repair can generate lots of lead dust.

- Broom sweep won't clean up lead dust.

- Lead-contaminated dust is invisible to the naked eye.

- Initially, lead poisoning can be hard to detect even people who seem healthy can have high blood levels of lead. Signs and symptoms usually don't appear until dangerous amounts have accumulated.

- Lead usually targets the oxygen-carrying protein in red blood cells (hemoglobin) first. In time, it attacks the nervous system.

BEFORE conducting any renovations on older buildings, it's important to understand the hazards that may be discovered as construction continues. Determining if the interior or exterior paint contains lead, if any materials of construction contain asbestos, and if water intrusion has occurred anywhere in the building during its lifetime (wet building materials are a food source for mold) is the first step toward creating a healthier building.

Emilcott regularly assists clients who face building environment investigations such as indoor environmental quality, asbestos and lead management, microbial contamination and vapor intrusion. Our EHS staff work with building managers to quickly learn how their buildings operate, diagnose conditions, complete inspections of building systems, interview occupants, and advise on the best course of action to ensure that the building is a safe place to live, work or play.

Interested in reading more on keeping buildings healthy? Other EHSWire blog posts about building environments include:

Topics: Emilcott, health and safety, General EHS, Construction H&S, EPA, H&S Training, Compliance, worker safety, Air Sampling, Mold, asbestos, Exposure, environmental air monitoring, Respiratory, lead, lead-based paint

When the National Weather service issues a forecast calling for 3 to 4 inches of rain, most people react by wondering how it will affect their plans or travel. I think about what water damage will occur.

When heavy rains are forecast, are you ready? Do you know what to do if your building is affected by rain penetration through the roof or walls? What is your plan if your building is flooded by a local stream or river? Even without bad weather, water damage is always a possible threat if your building has a water line break. Or worse yet, do you know how to react if theres a sewage back-up?

Depending on the water source your options for cleaning up and salvaging property vary greatly. But for all kinds of damage, you need to have a plan in place anticipating what you will do, who you will call, and how quickly they will respond. Emilcott was recently asked to work in four, very different, water-damaged commercial and/or multi-tenant residential properties. These events included:

- Retail and Office Complex Roof and Façade Leak

- Office and Warehouse Broken Water Supply Main

- Multi-tenant Apartment building Sprinkler Activation

- Public Housing Complex Steam Leak

What did all four projects have in common? The answer is time. Lots of time! Too much time between the initial event, the response and Emilcotts resulting late involvement! Time and water combined can grow to be an expensive and time-consuming enemy. Failure to respond promptly will, very likely, result in mold growth within the building requiring significantly more demolition than if the condition is handled in a timely manner. What is the definition of timely? As soon as it is discovered!

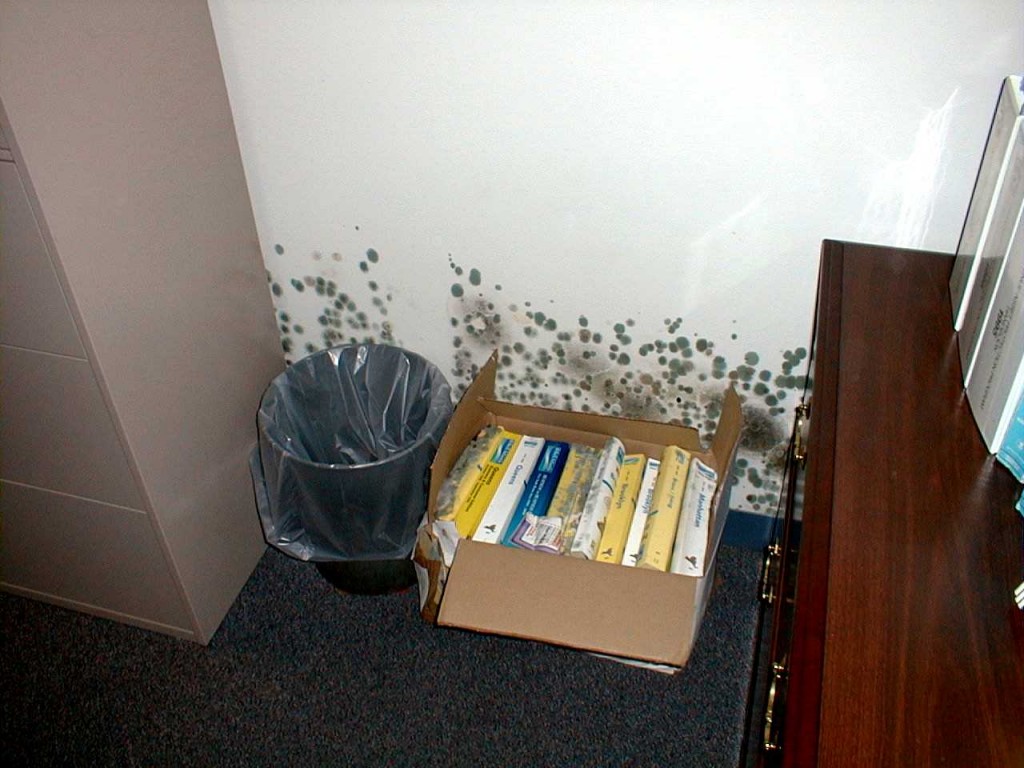

With the retail complex, we were called in approximately one month after the roof and walls began leaking. An employee actually complained to their nearest OSHA office and OSHA issued a notice of potential violation to the employer. Mold was present in a localized area of the store, along with a significant insect infestation due to wet, damp conditions of building surfaces. Unfortunate results of the delay: a mold remediation project was required and portions of the retail space were out of use for weeks.

The damage to the office and warehouse operation was more significant. Water from the broken water main filled the 5400 sq. ft. office to several inches and made its way to the adjacent warehouse. The initial response by the building owner seems logical: removal of standing water, placement of a few box fans to attempt to dry the carpet, and operating the air conditioning 24/7 as cold as the occupants would tolerate. By the time we arrived just 5 days after the event, sheetrock walls were saturated at the base of every wall and elevated moisture readings were present up to 8 feet above the floor. Relative humidity was close to 70%, carpets had a strong musty odor, and internal wall cavities were impacted by mold growth even though no visible growth was observed on the exterior of the wall. Final results of a mere 5 day delay in appropriate responsiveness: the tenant and their sub-tenants loss use of the office area as trailers were brought in to house them while remediation and reconstruction occurred over a two week time period.

A kitchen fire occurred in the residential apartment complex triggered sprinklers to turn on which caused water to run from the sixth floor down to ground level. Removal of standing water was the only initial response. When Emilcott arrived 2 weeks later sheetrock walls were still saturated with water, visible mold was appearing in multiple, occupied apartments, and paint was bubbling and peeling from the walls. Another significant mold remediation project was required, which in turn required relocation of tenants while remediation was in progress.

Finally, the public housing complex had experienced a steam leak for a period of several months. Tenants in effected units were relocated and those apartments remained unoccupied. However, an unusual occurrence happened with this steam leak as these apartments had plaster walls. Mold grew quite well on the painted surface of the walls, something that may be expected, but due to high, high humidity and moisture levels in the plaster for extended periods of time, the analytical laboratory verified that the mold growth penetrated into the plaster from the surface. This resulted in the demolition of the plaster walls and loss of effected housing units for several additional months.

For each of these properties and water-related circumstances, delayed and improper response increased the magnitude of the problem resulting in increased time that each space was unusable, and increased the total cost of response and repair. What should you do instead? Bringing in a water-remediation expert immediately to identify the scope of the problem, develop a water response action plan, and implement that plan right away will minimize the damage to building materials and reduce impacts to building occupants. In each of the four instances listed above, response actions like relocating furnishing away from walls or out of the area completely, immediately removing cove moldings, installing commercial grade dehumidification equipment, installing commercial grade floor fans, selective limited demolition, and actively monitoring and evaluating the drying process would have significantly reduced the duration of the response activity and the overall cost of each event.

So, how can you reduce the costs of the surprise water problem? My advice is to plan now -- whether it is for rain and flooding that may occur due to weather conditions or for the pipe break that always happens unexpectedly. Knowing who to call to determine the scope of the problem and who can implement the recommended response will save you significant time, money, property and hassle.

Topics: OSHA, indoor air quality, health and safety, General Industry H&S, General EHS, Construction H&S, EPA, Air Sampling, Mold, environmental air monitoring, Respiratory, Water Response Plan

10 Items You Need To Know About Water and Mold Damage In A Commercial Building

Posted by Shivi Kakar

1. The uncontrolled release of water may result in mold (fungi) growth in a previously non-water damaged area of a building if the water release is not adequately addressed within 48 hours of its occurrence. In addition to mold growth, water damaged can result in structural damage and support the proliferation of other types of biological organisms including dust mites, cockroaches, rodents, algae, and/or bacteria.

2. The uncontrolled release of water in a building with a history of water damage may cause dormant mold colonies from prior water releases to become active in less than 48 hours.

3. One of the most important factors in effectively preventing or controlling mold growth inside a commercial building is to have a written Water Response Plan in place before an uncontrolled release of water occurs.

4. An effective Water Response Plan will include provisions to immediately stop the uncontrolled release of water and prevent its reoccurrence.

5. An effective Water Response Plan will include provisions to immediately start removing the water by mechanical means such as extraction with wet vacuums and the use of commercial-grade drying equipment. Areas where drywall (sheetrock) are covered by large pieces of furniture, wallpaper, or cove base/moldings may require special attention that potentially includes removal of sections of the drywall. The source of the water (domestic drinking water vs. rain penetration through the building vs. widespread flooding vs. sewage backup) will also impact the required response activity. Visible inspection, moisture meters, infrared cameras, measurement of temperature and relative humidity are all tools that that may be used to identify where water damaged materials exist.

6. Depending on the capabilities of the commercial buildings maintenance staff, the Water Response Plan should anticipate the use of outside contractors such as licensed plumbers, roofing contractors, environmental consultants, water/fire damage restoration contractors, and/or qualified mold remediation contractors. It is advisable to have an established relationship with each type of contractor in order to best control costs once the Water Response Plan requires activation.

7. The most common health effect resulting from indoor mold exposure is an aggravation of allergies and/or asthmatic conditions. Prolonged exposure may cause hypersensitivity in some individuals, resulting in these individuals experiencing a severe respiratory reaction even when very low concentrations of airborne mold are present at work or at home. The variety of responses is often seen when employees working in the same area report a wide range of individual responses when near the water damaged building materials.

8. If an uncontrolled release of water is not properly responded to mold growth will likely result. Once mold growth is suspected or confirmed a qualified individual should conduct an investigation to determine the extent of the mold growth and develop a Mold Remediation Work Plan. The Mold Remediation Work Plan should identify procedures to follow when cleaning or removing mold damaged building materials so that building occupants are protected and not adversely affected by the remediation project.

9. The Mold Remediation Work Plan must include: which building materials require removal; which building materials require cleaning and disinfection; a plan for the isolation of the work area using barriers (polyethylene sheeting) and negative air machines to control airborne dust generation; documentation of worker training in proper mold remediation work procedures; and the criteria of the Post Remediation Assessment. Simply put, spraying with bleach or covering with an anti-microbial paint is not an appropriate response where mold growth is confirmed to be present on installed building materials.

10. A Post Remediation Assessment (PRA) determines if the Mold Remediation Work Plan was successful in returning the area to non-water damaged condition. The PRA must be conducted prior to the removal of isolation barriers and should include: a visual inspection to confirm water and mold damaged has been removed and the area has been appropriately cleaned; a moisture survey, using moisture meters, to document remaining installed building materials are satisfactorily dry; and confirmation that corrective actions are in place to prevent additional water damage. Depending on the extent of the mold damage air and surface samples may be collected as part of the PRA. Whenever air or surface samples are collected a qualified individual, such as a Certified Industrial Hygienist, should be chosen to determine the sample locations and assist with the interpretation of results.

Topics: health and safety, Construction H&S, worker safety, Occupational Health, Occupational Safety, Mold, Occupational Training, Working Green, Water Response Plan

Medical Records: Employee Rights & Employer Responsibilities

Posted by Shivi Kakar

Topics: OSHA, health and safety, General Industry H&S, Construction H&S, H&S Training, Compliance, Occupational Health, Mold, Fire Safety, Medical Records